Intelligent Logistics

Ensuring integrity of process at scale

Give devices a second life – in record time through intelligent automation

We understand that as a logistics provider you need to work at a tremendous scale and speed and process devices quickly and cost effectively. What we often see is that manual processes and fraud checks can get in your way. In addition, complex processes and training may slow you down further.

Our dDLM platform helps you change the engine while operating to deliver higher units per hour, more productive line operators and optimized device margins.

Intelligent automation at work to maximize units per hour

Some solutions promise more than 30 units per hour (UPH) which can only be realized under laboratory conditions. The reality is often only 15-20 UPH. MCE’s solution and implementation experience help you optimize UPH through automation, guided flows and fast-tracking devices based on gathered insights.

Your line operators will thank you

While UPH goes up, thanks to better intelligence and upstream connectivity, your line operators can easily keep up with the pace change. There are multiple events where the productivity driver is empowering the operator to work faster while feeling less pressure.

There is one comprehensive training. Typical retraining needs such as OEM and grading updates are completed in the background and do not effect the operator’s work. The use of guided flows avoids mistakes and rework through enforced objectivity. Manual steps are replaced by end-to-end automation, e.g., simplifying device recognition and lock detection, grading decision, fraud detection, running in the background.

Optimize device margins

There are three key levers to help you optimize device margins, higher cycle time acceleration, pre-shipment information and turning inoperable devices into sellable devices.

- Realize higher average selling price (ASP) thanks to cycle time optimization

- Save costs through leveraging pre-shipment information

- Make inoperable device sellable, unlocking untapped revenues

For operators using MCE upstream, there are additional benefits: knowing the grade helps determine the right destination prior to arriving at central depot, i.e., buffing & re-kitting of devices good enough to resell, refurbishment if net margin is higher than immediate selling, normal processing in depot.

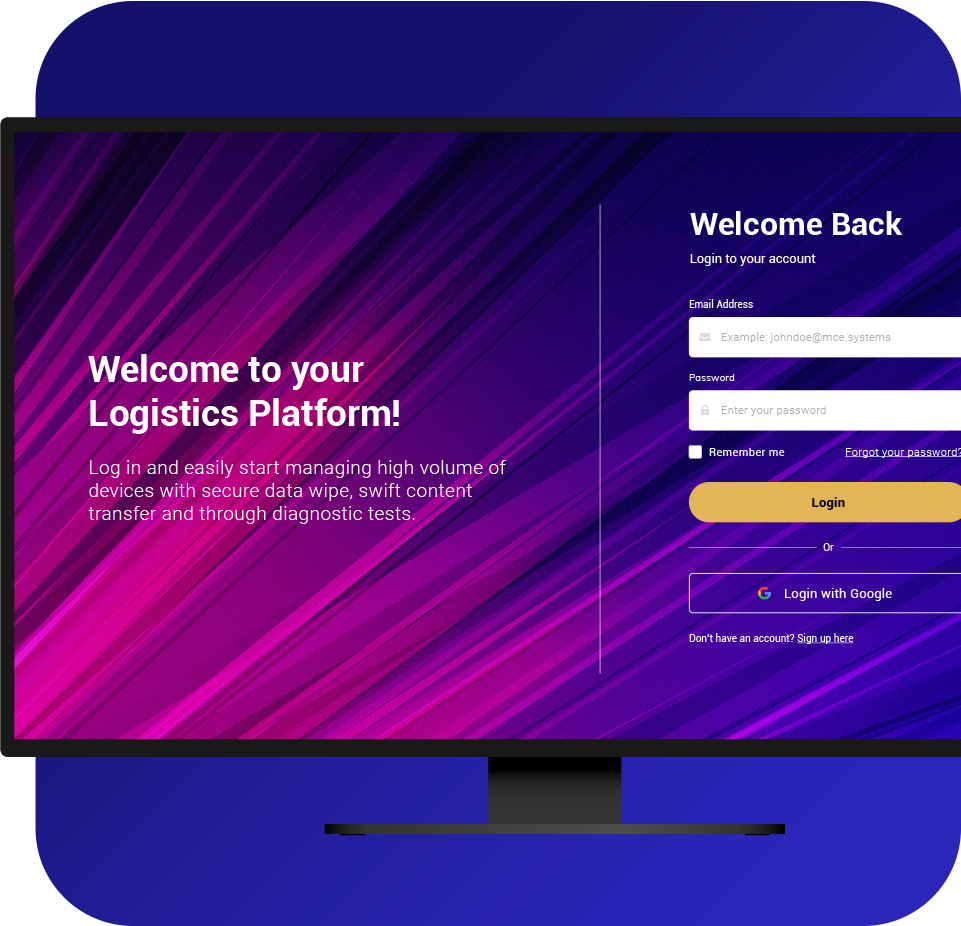

MCE’s Logistics Platform

Our logistics solutions help for both for the reverse and forward logistics areas.

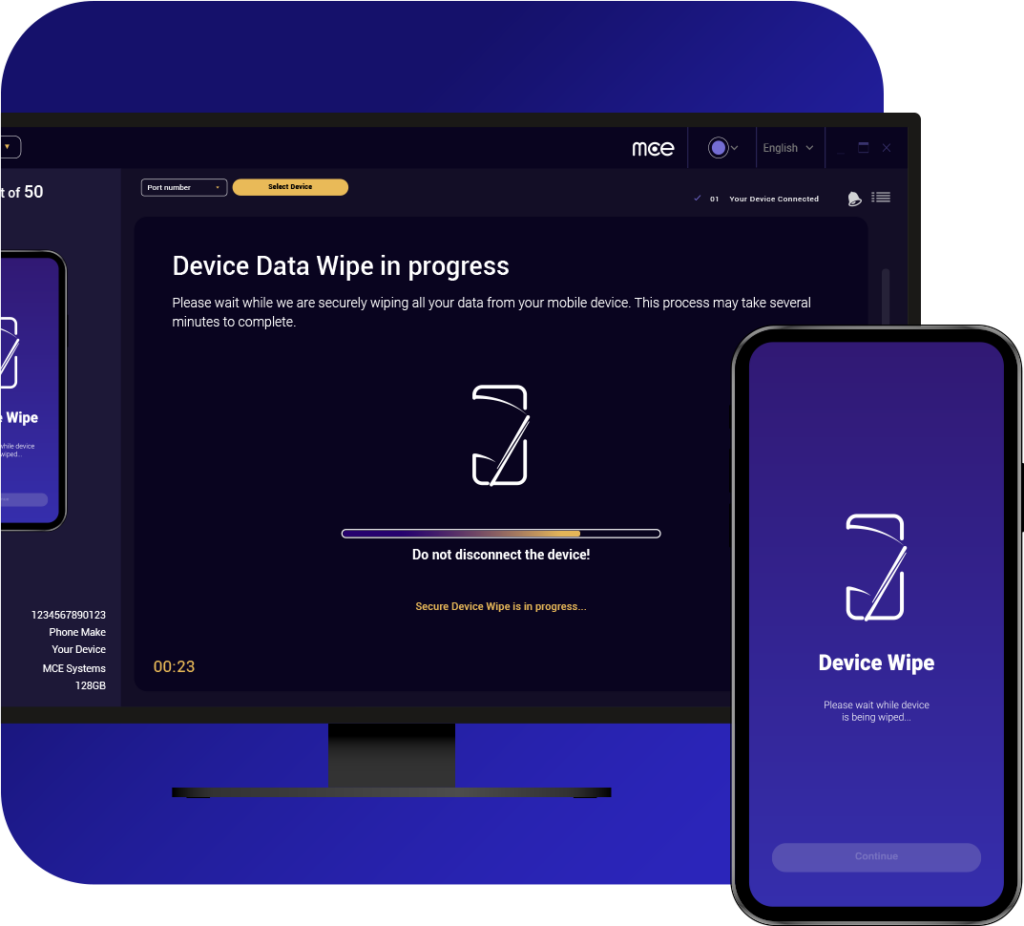

Receiving

- Receive

- Record device to inventory

- Upload assets to device

- Lock test, wipe and secure device

Grading and triage

- Identify hardware issues using diagnostics

- Grade device based upon hardware functional status

- Flash to most recent operating system software

- Perform cosmetic assessment

- Route it to different channels

Forward logistics

For devices re-entering distribution networks, we streamline device staging – enabling the preloading of device profiles (including app bundles, settings, media) at scale, according to your requirements.